STANDARD QM FUNCTIONS

Titanium.aero covers the following central QM functionalities as standard: Test equipment management Test equipment capability analysis Production control and steering plan Inspection orders/inspection order monitor Quality data acquisition (QDE) Control chart/process capability (cpk) Complaint processing (8D report) Scrap and blocking quantity recording/defect collection cards Batch tracing (single and multi-level)

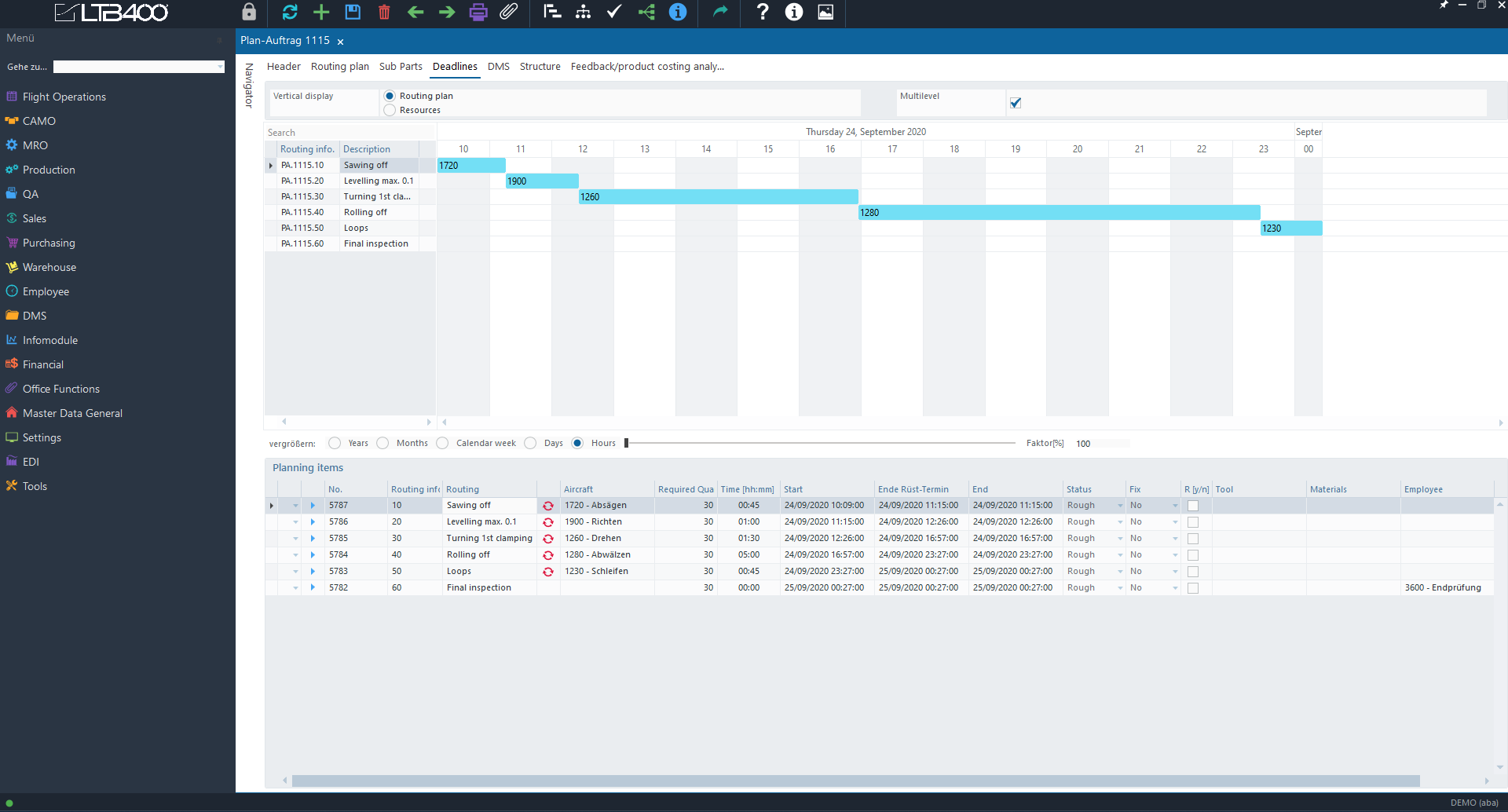

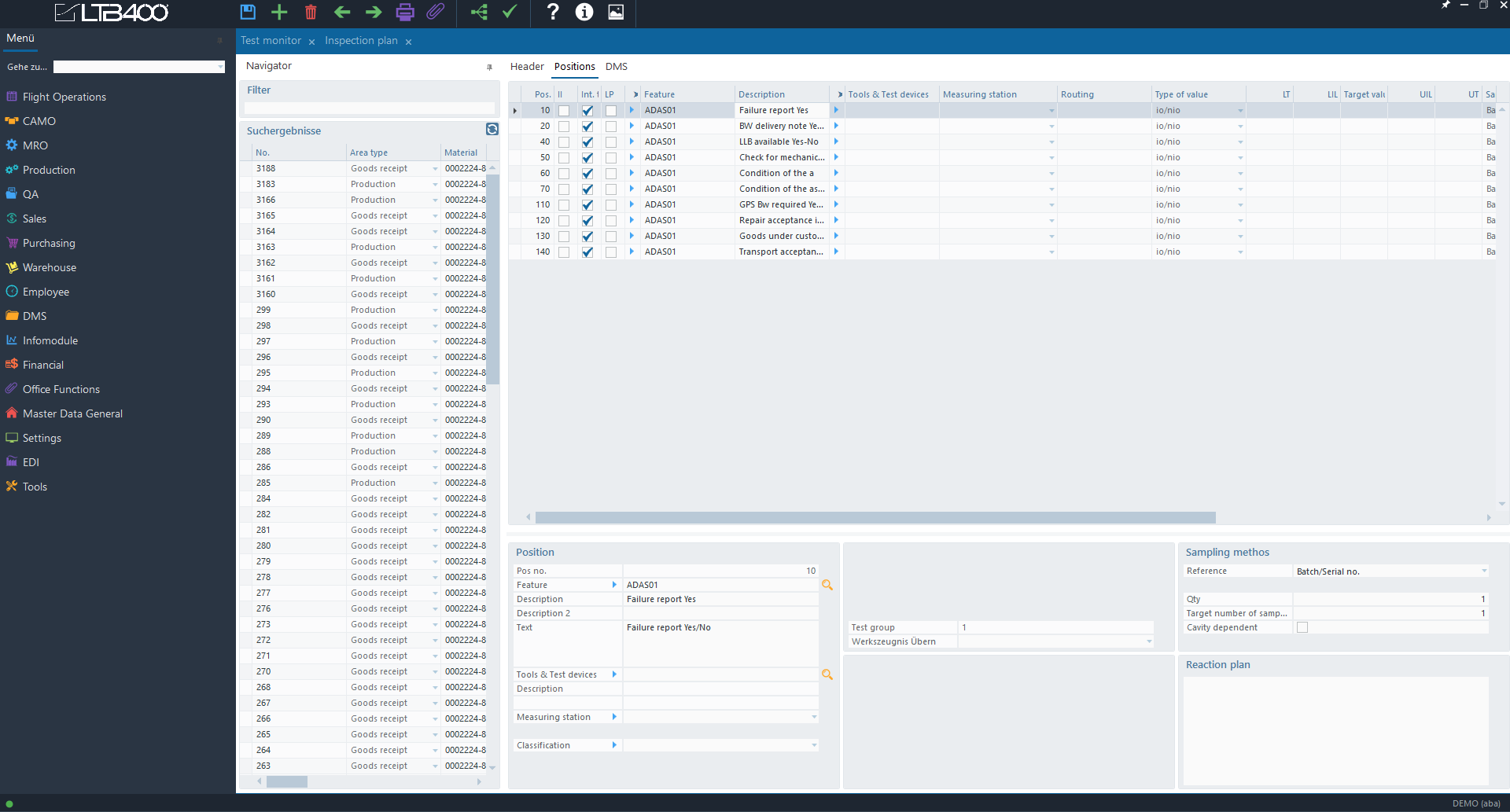

PRODUCTION CONTROL PLAN

In the Production Control Plan, the work plan, inspection plan, parts list, and FMEA as well as photos for inspection instructions and all technical documents are recorded in one module. Example :- Index change: In the event of an index change, the PKP is simply copied to the new index. This prevents confusion between the

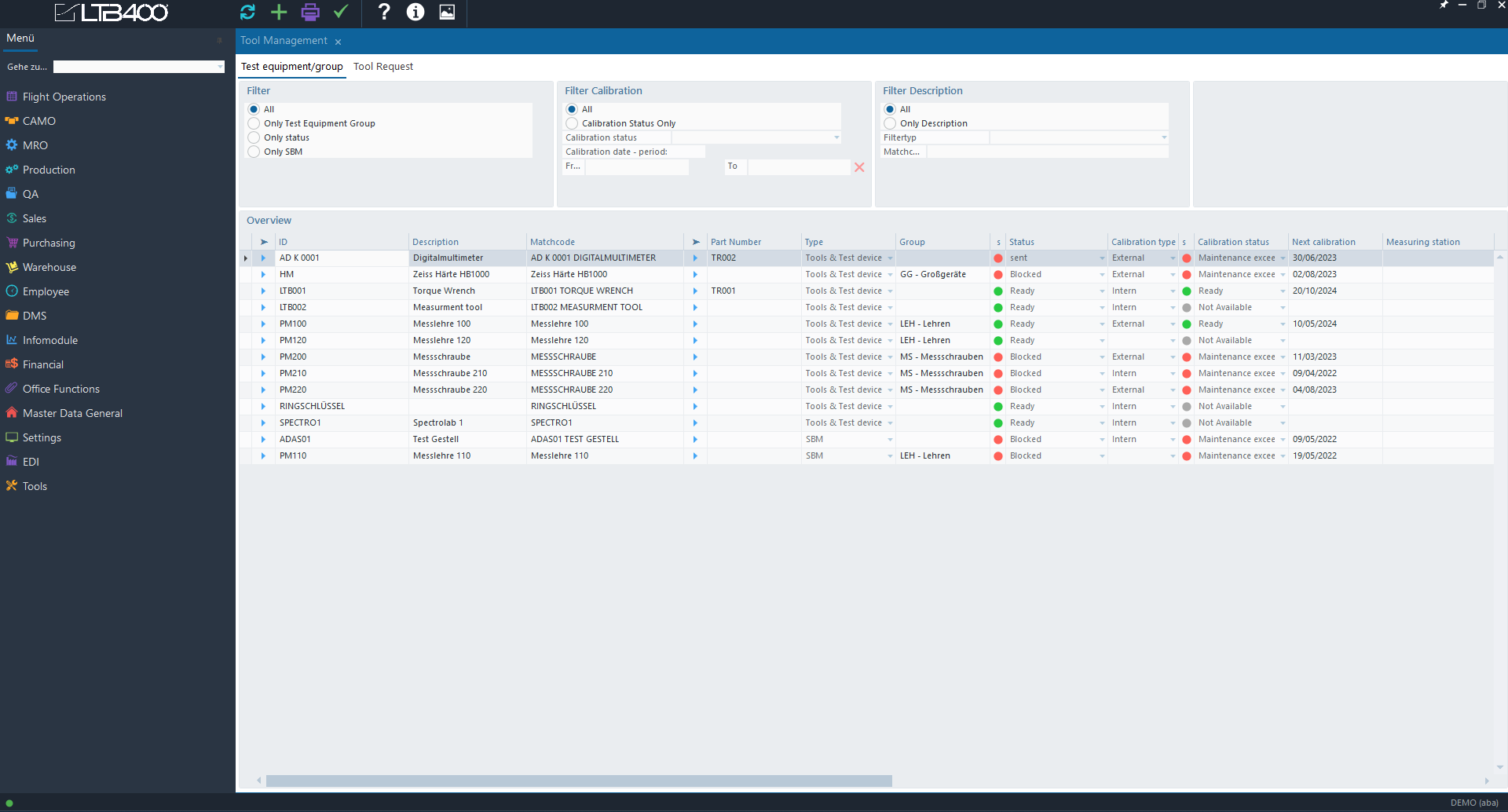

TESTING EQUIPMENT MANAGEMENT

Reliable management of Tools/ Test equipment including calibration. Test and calibration intervals, calculation of due test and calibration dates, automatic warning message when due dates are exceeded, recording of calibration and test results, internal and external commissioning of calibrations and tests, barcode application possible, overview of the availability of test equipment, usage history of tools

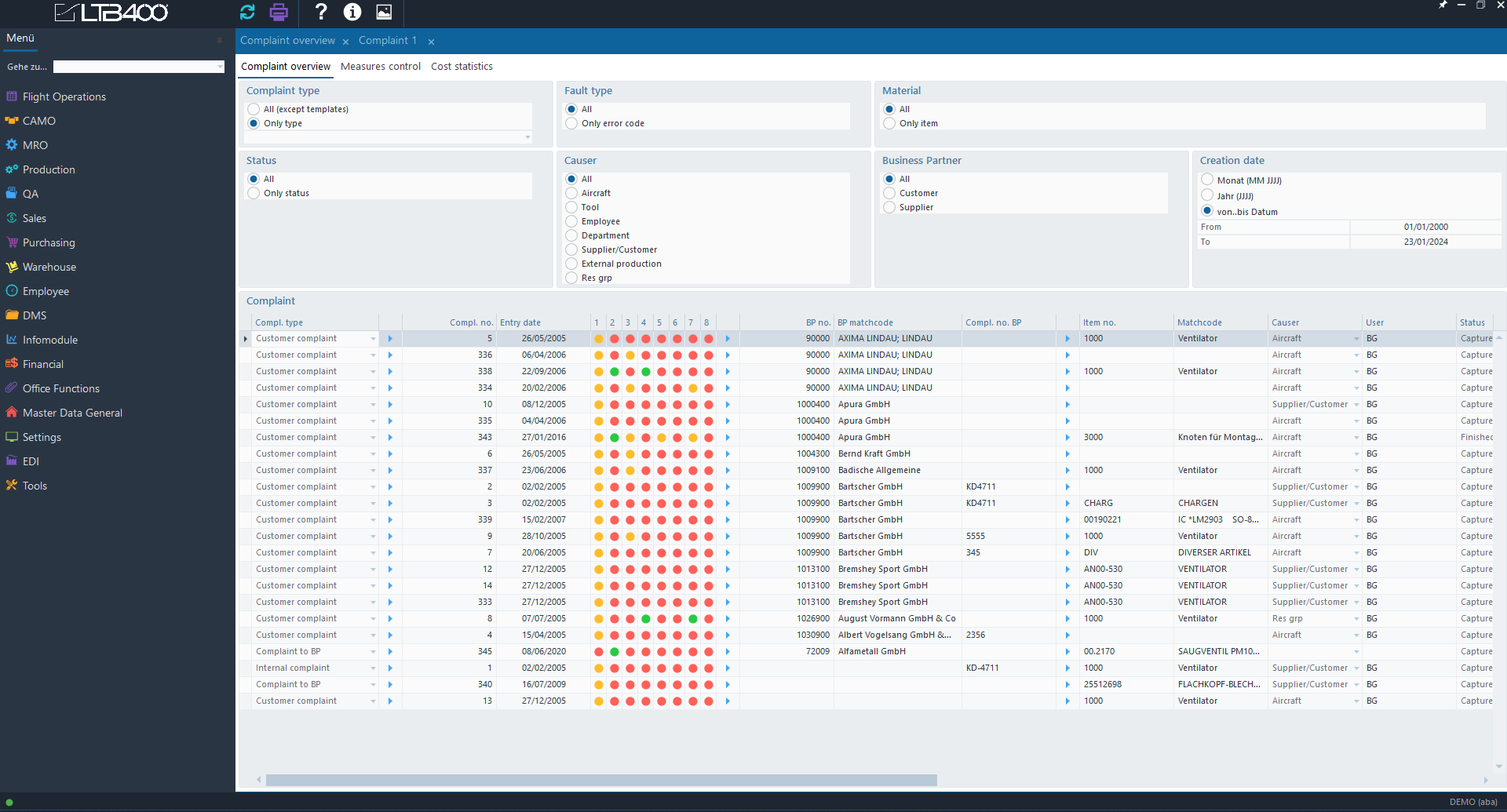

COMPLAINT HANDLING

Process complaints using the 8D report procedure and evaluate them according to various criteria.

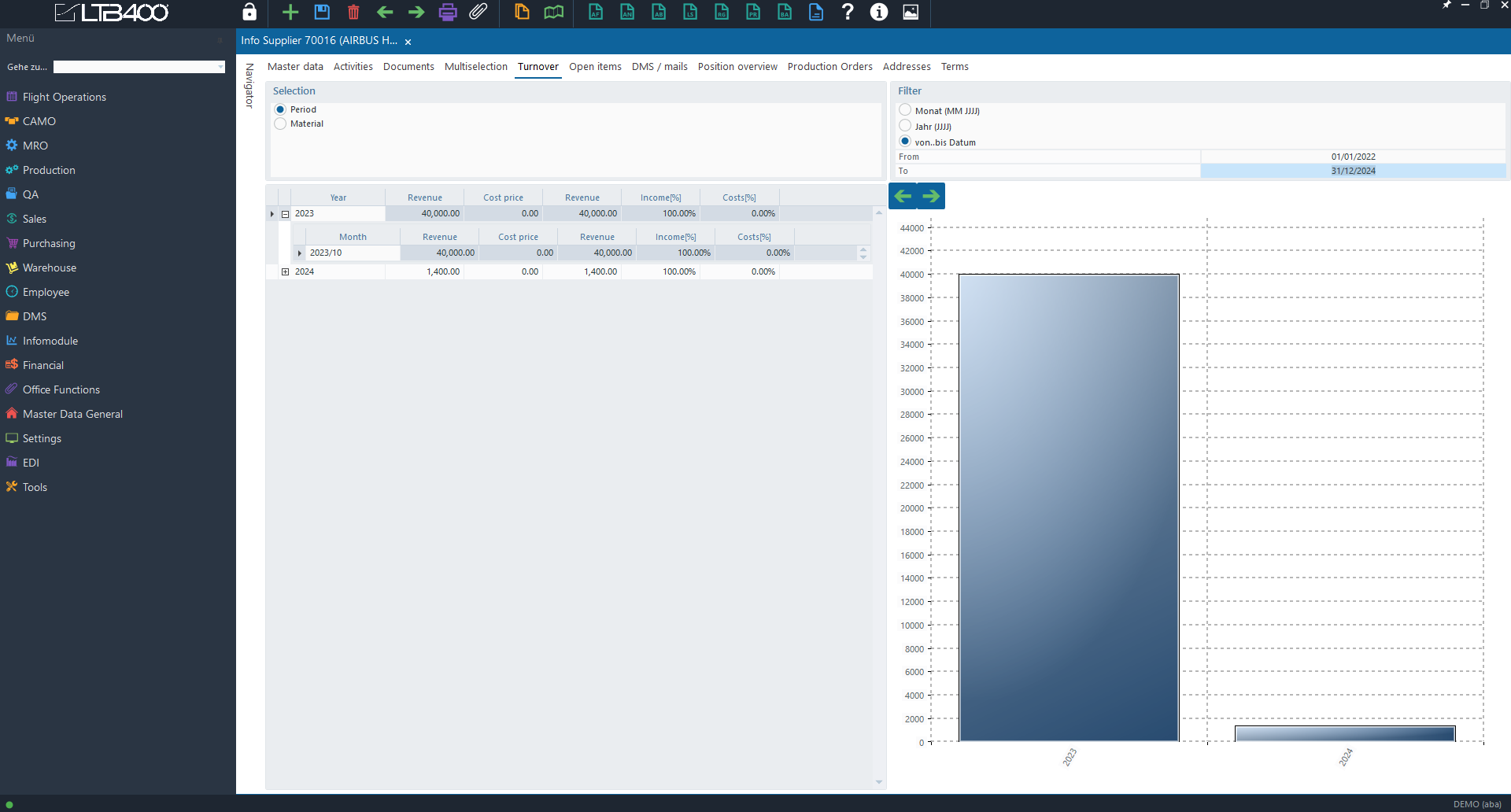

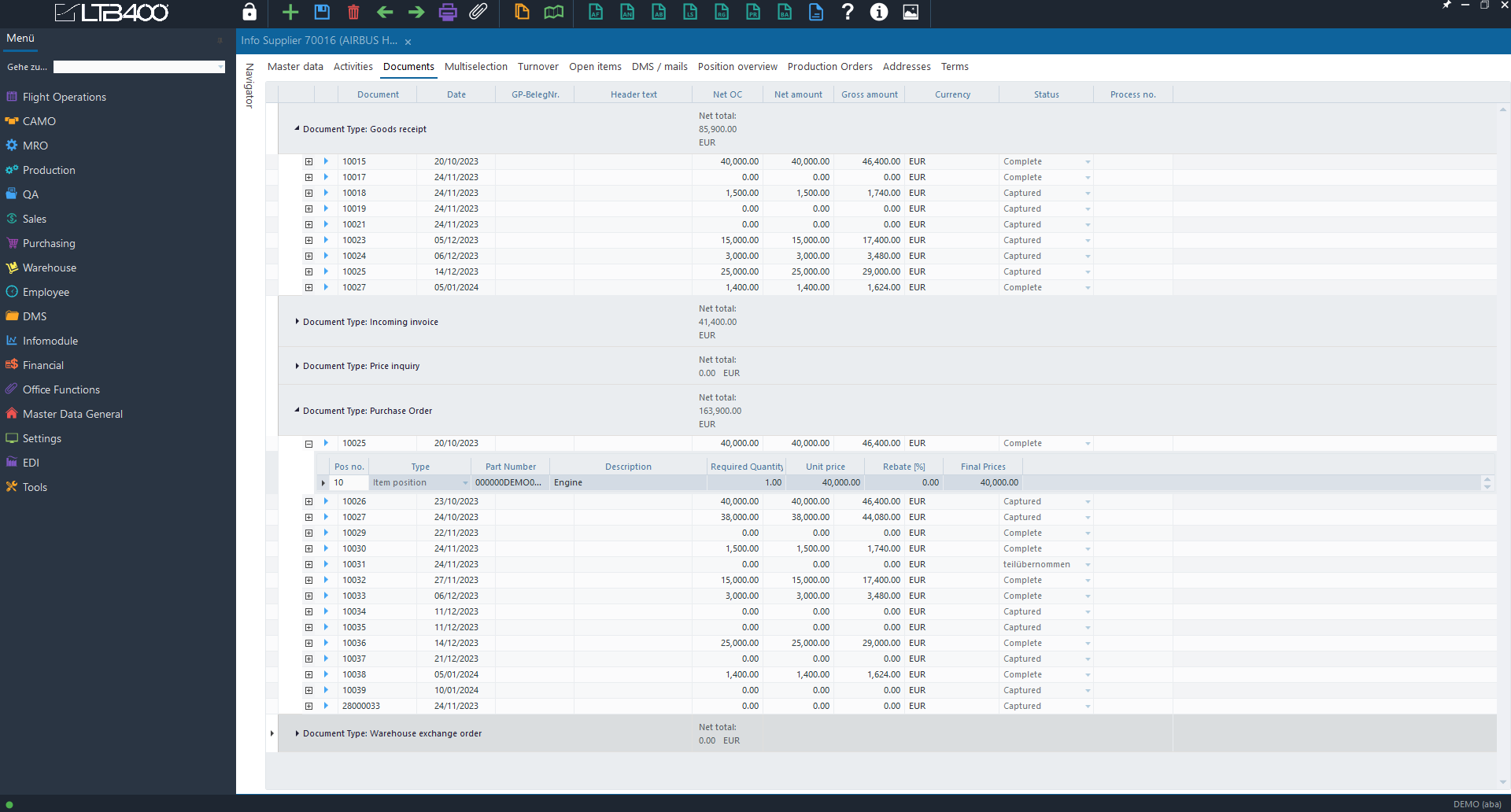

SUPPLIER EVALUATION

Definition of any number of evaluation criteria (points, quotas, free text); optional query of criteria when entering incoming goods; automatic evaluation of standard criteria (adherence to delivery dates, reject rate, price stability, price basis); evaluation. In addition to preset parameters, the supplier evaluation in Titanium.aero also offers individually configurable "hard" and "soft" facts that can

QUALITY ASSURANCE

Process control charts including original value, mean value, standard deviation, range and PPM statistics can be displayed graphically.

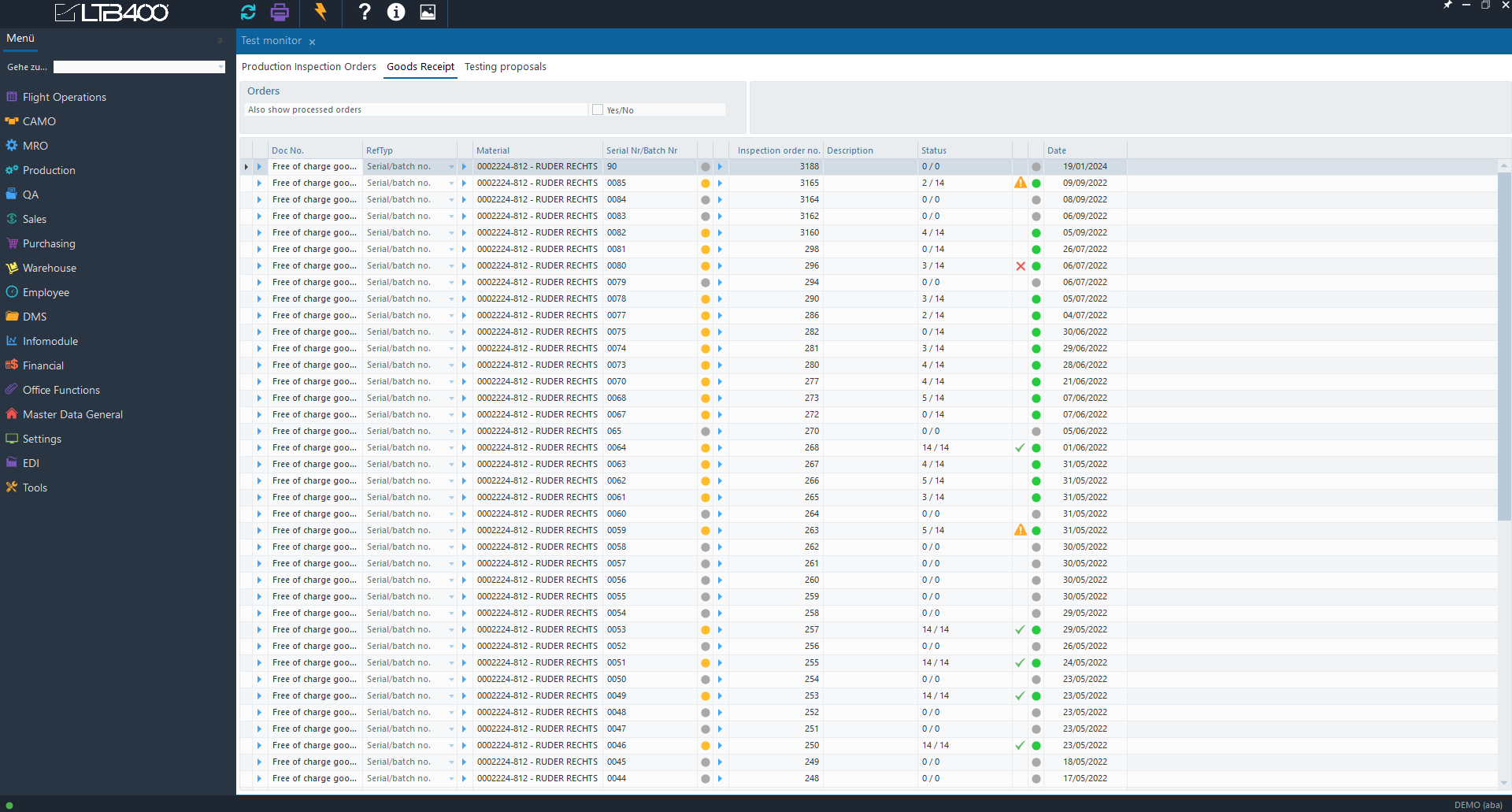

BASIC MODULE QA

QA certificate and Validity date, Inspection plans, Inspection orders and recording of measured values (on paper and digital), First Article Inspection report EMP (First Article Inspection FAI EN 9002), Acceptable Quality Limit (AQL) evaluation, 6-level complaint code matrix.