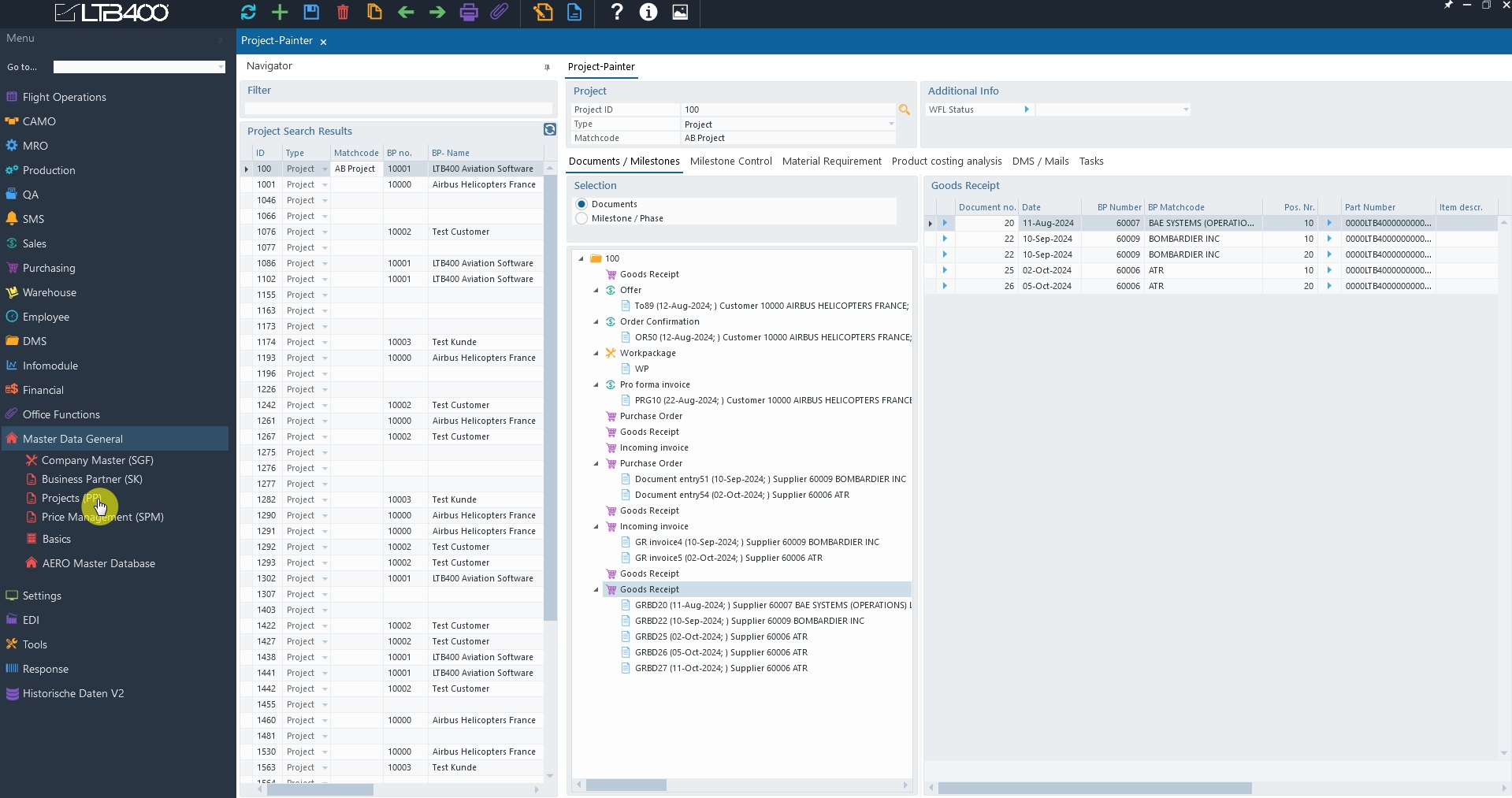

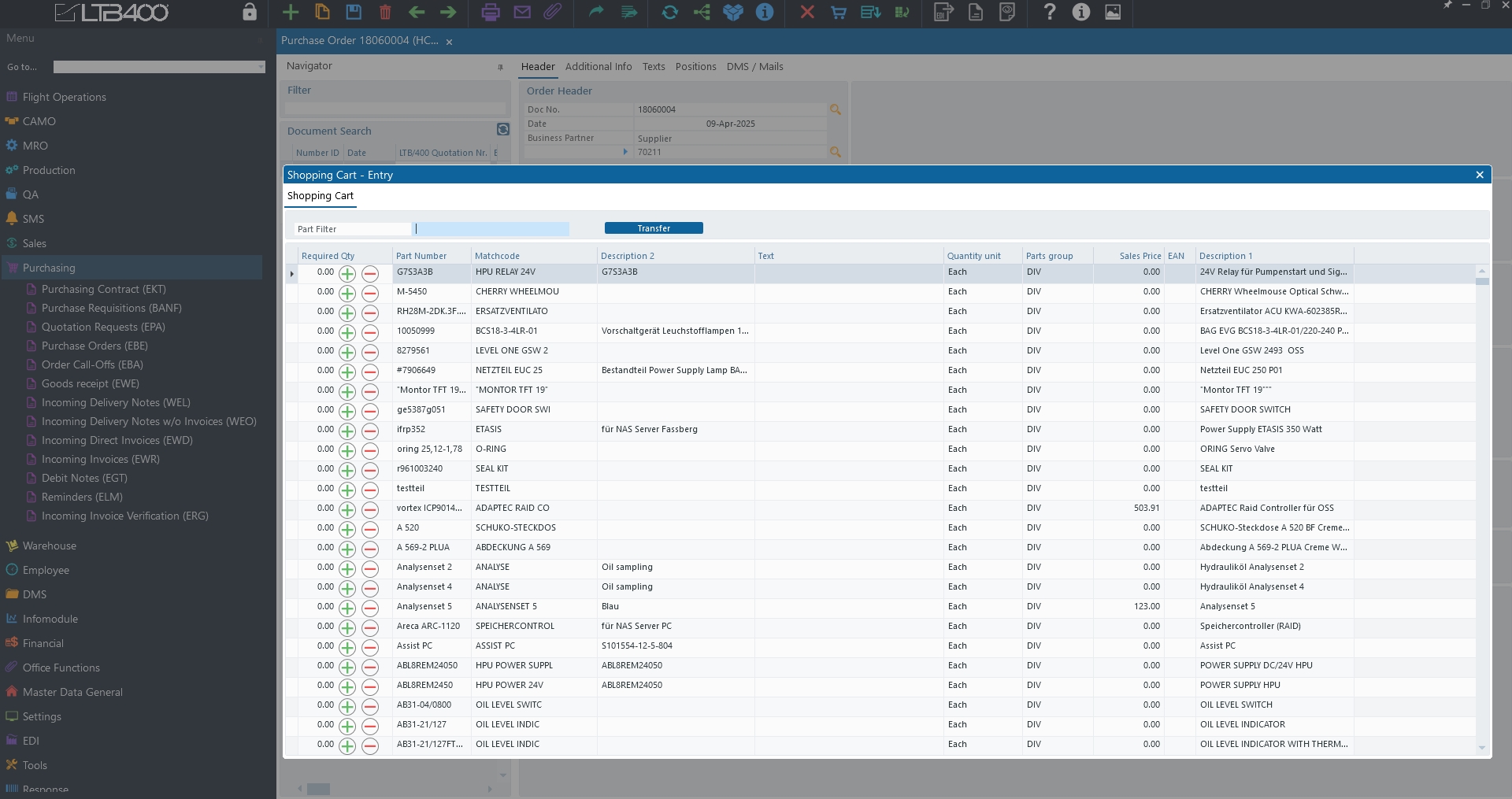

Efficient inventory and tool management are crucial for reducing downtime and ensuring seamless maintenance operations. The Inventory & Tool Management system in titanium.aero provides end-to-end visibility and control over spare parts, consumables, and specialized maintenance tools. Helicopter and VTOL operators can track stock levels in real time, set automated reordering triggers, and prevent shortages that could delay critical repairs. The system supports multi-location inventory tracking, allowing operators to manage stock across different bases and warehouses with ease. Barcode scanning capabilities enhance accuracy, ensuring that parts are easily located and accounted for. Additionally, our software streamlines tool tracking, ensuring that essential maintenance equipment is always available when needed. Technicians can check tool availability, schedule calibrations, and prevent unauthorized usage, reducing the risk of misplaced or unserviceable tools. By integrating with procurement workflows, the system optimizes inventory costs, minimizes waste, and ensures that only certified and approved parts are used in maintenance operations.

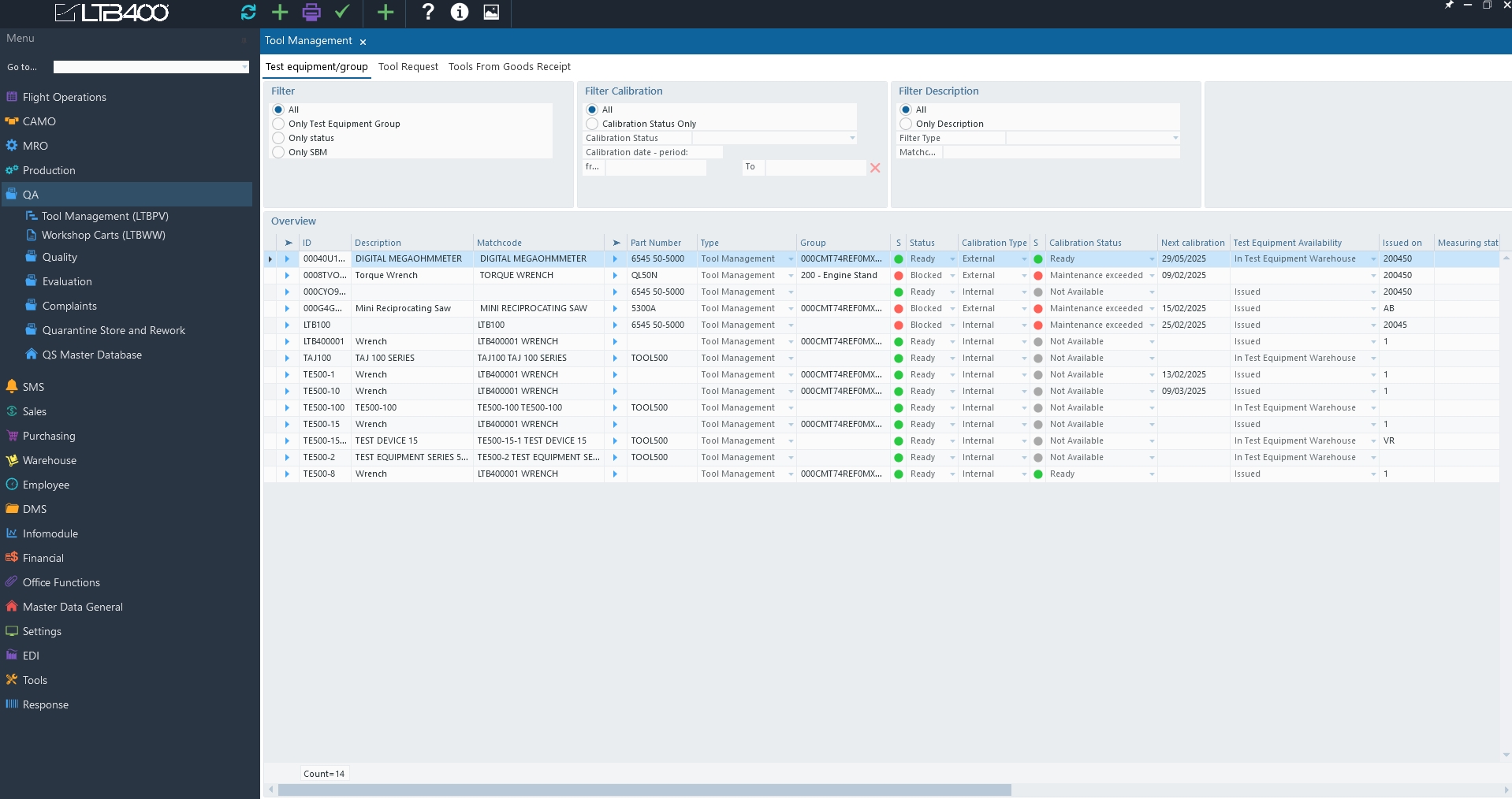

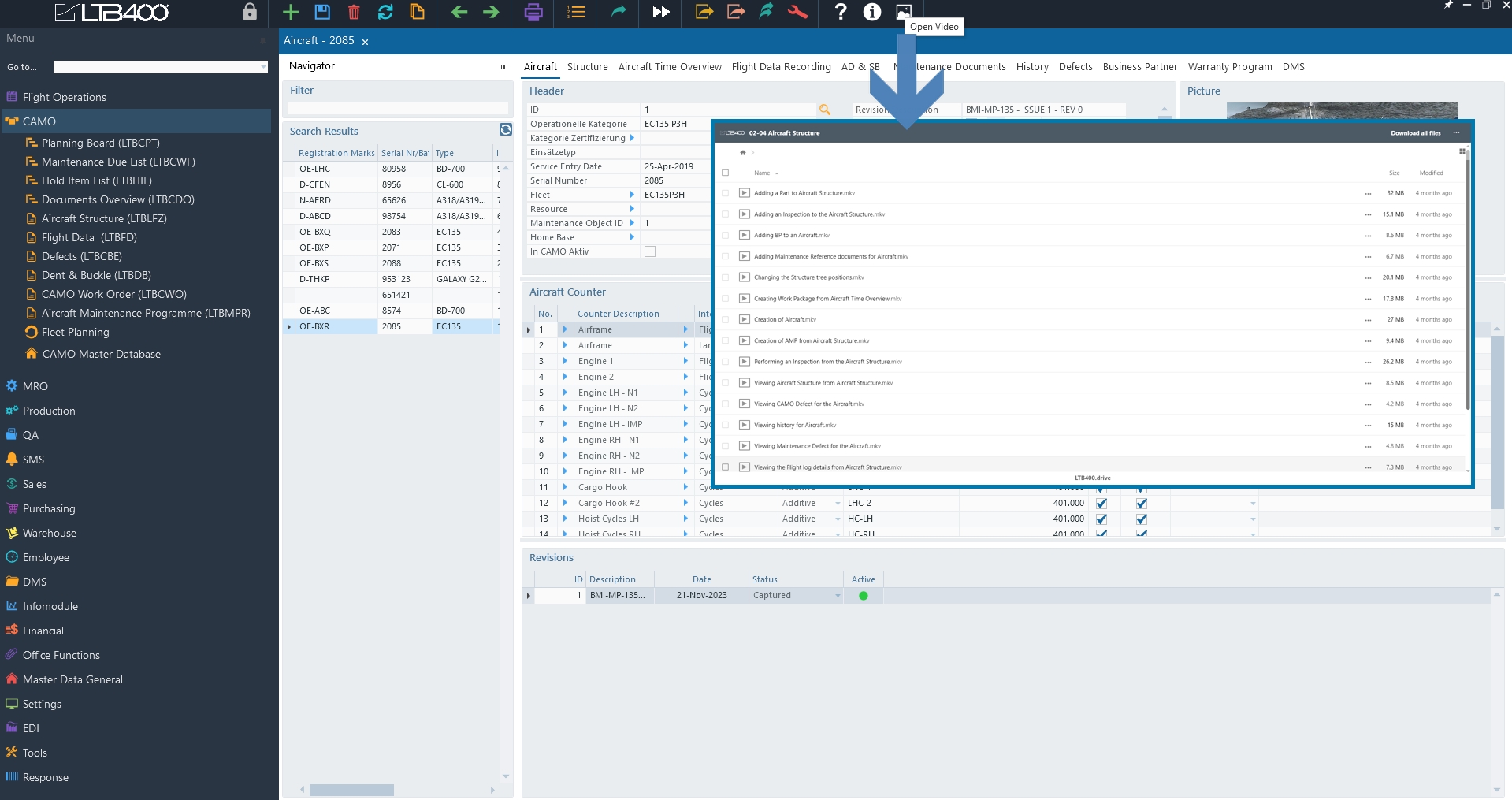

Tool Management

Control your tool pool with real-time tracking, usage logs, and calibration alerts

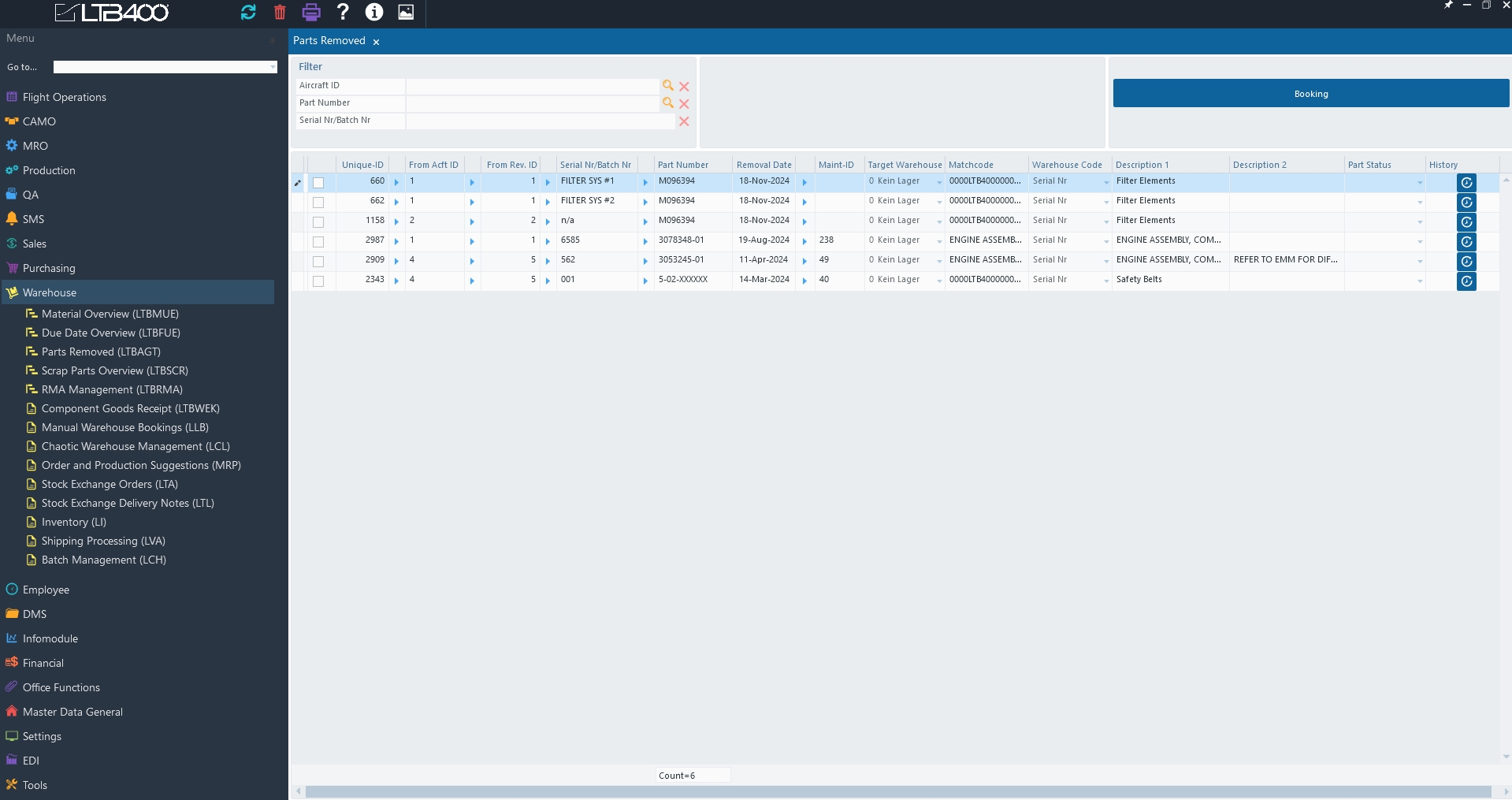

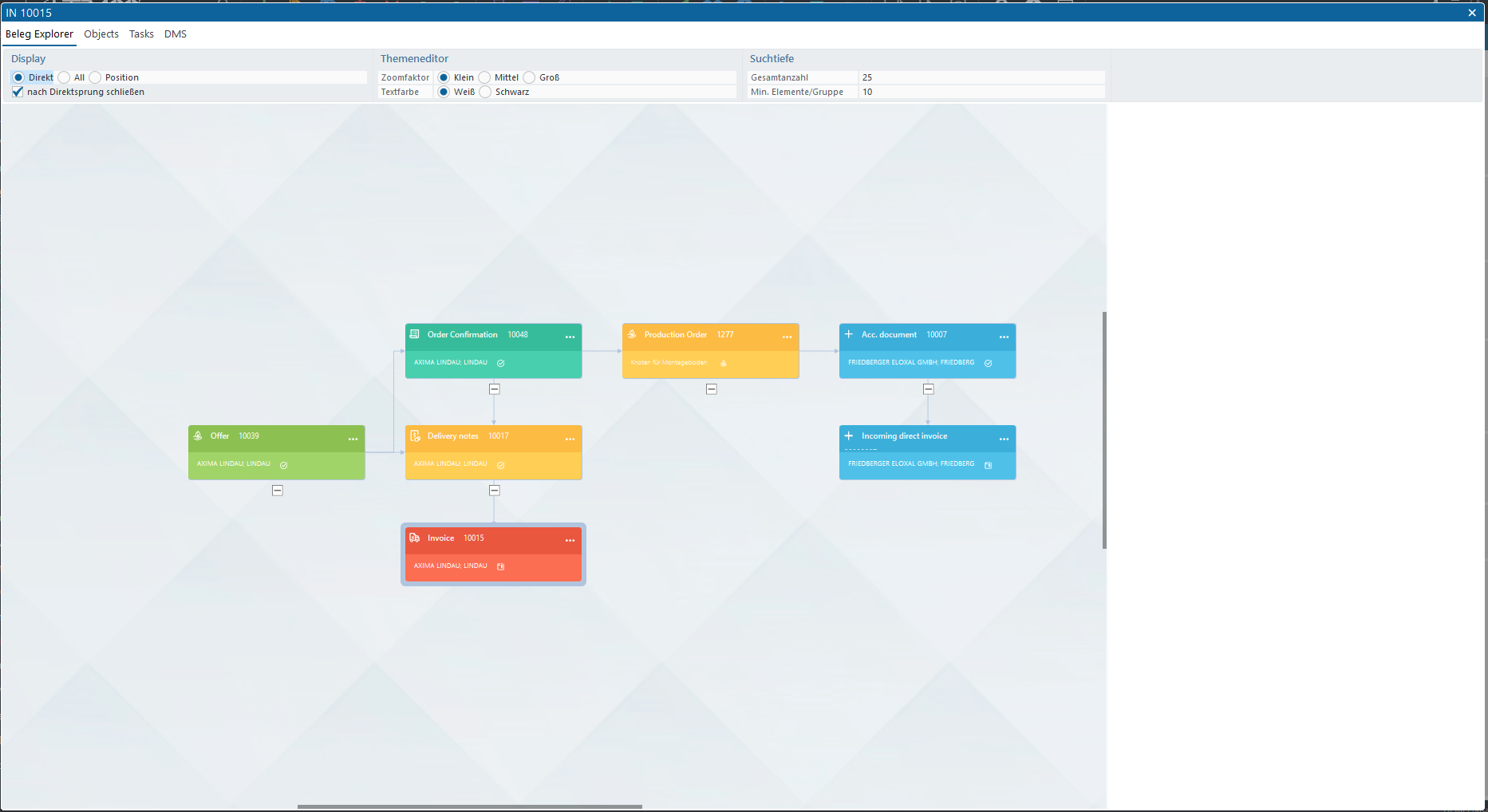

Removed Parts Management

Track removed components with full traceability for repair, reuse, or disposal

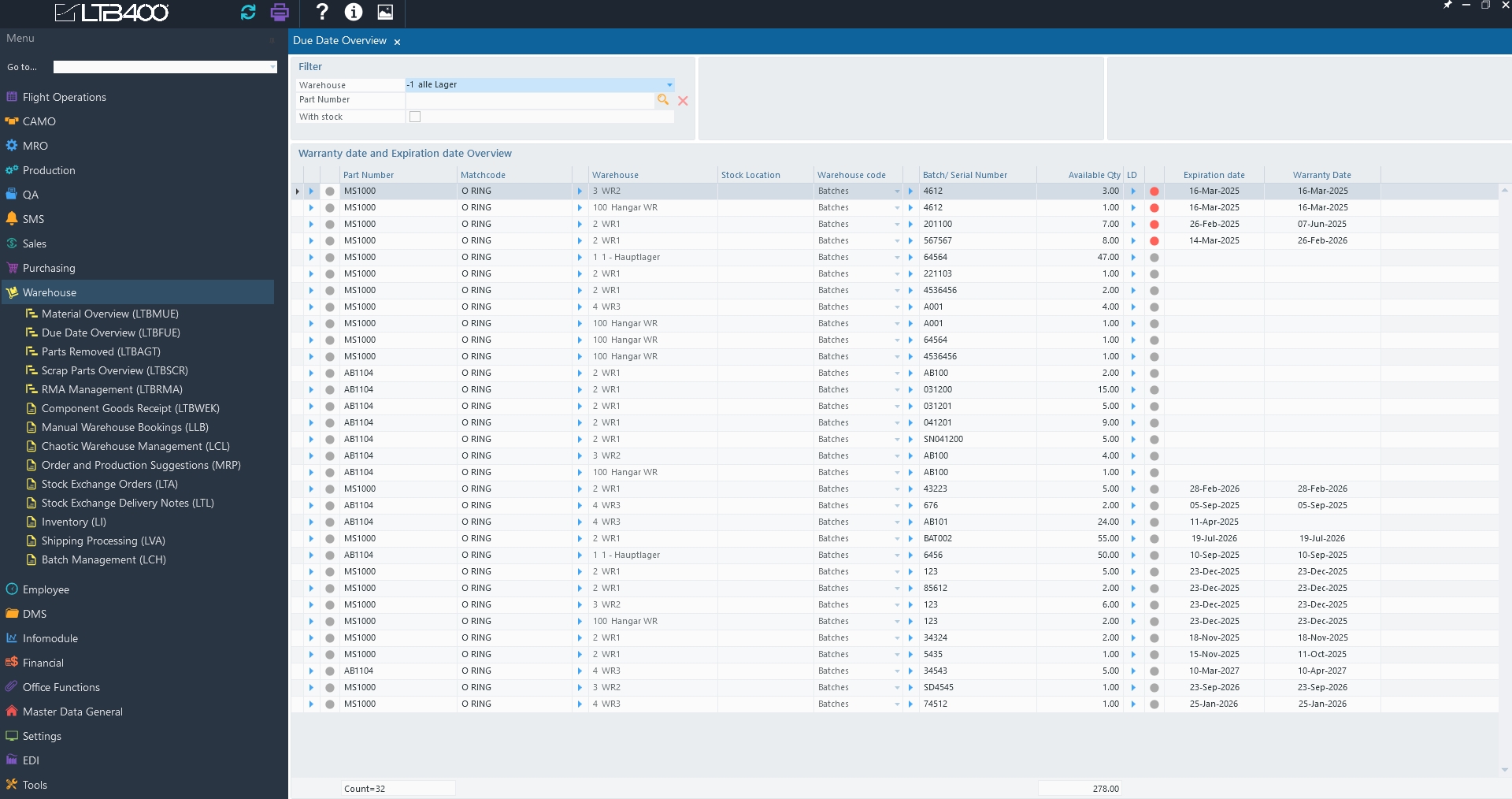

Expiry & Warranty Tracking

Never miss a deadline—automated alerts keep you ahead of expiries and warranty windows