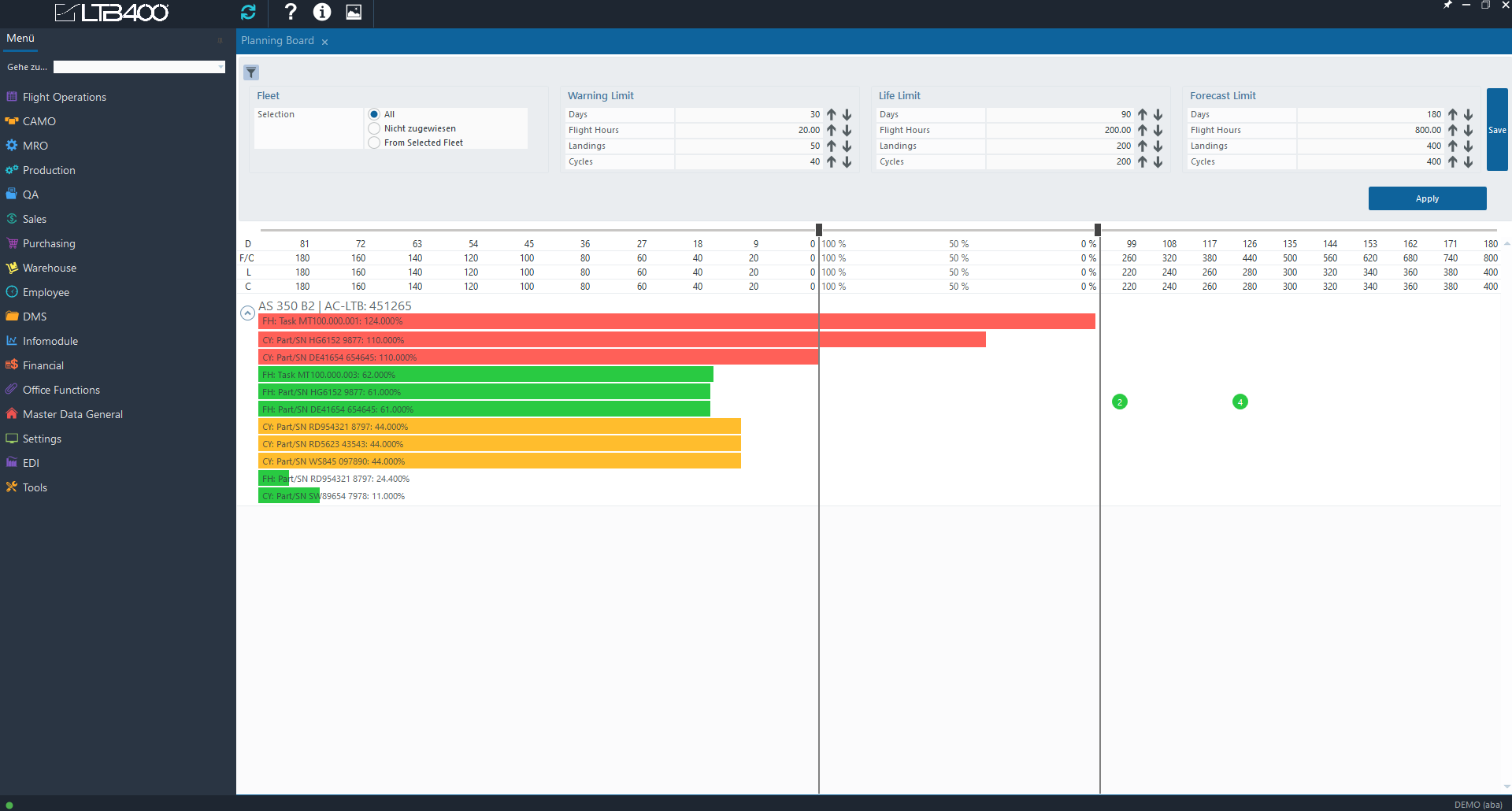

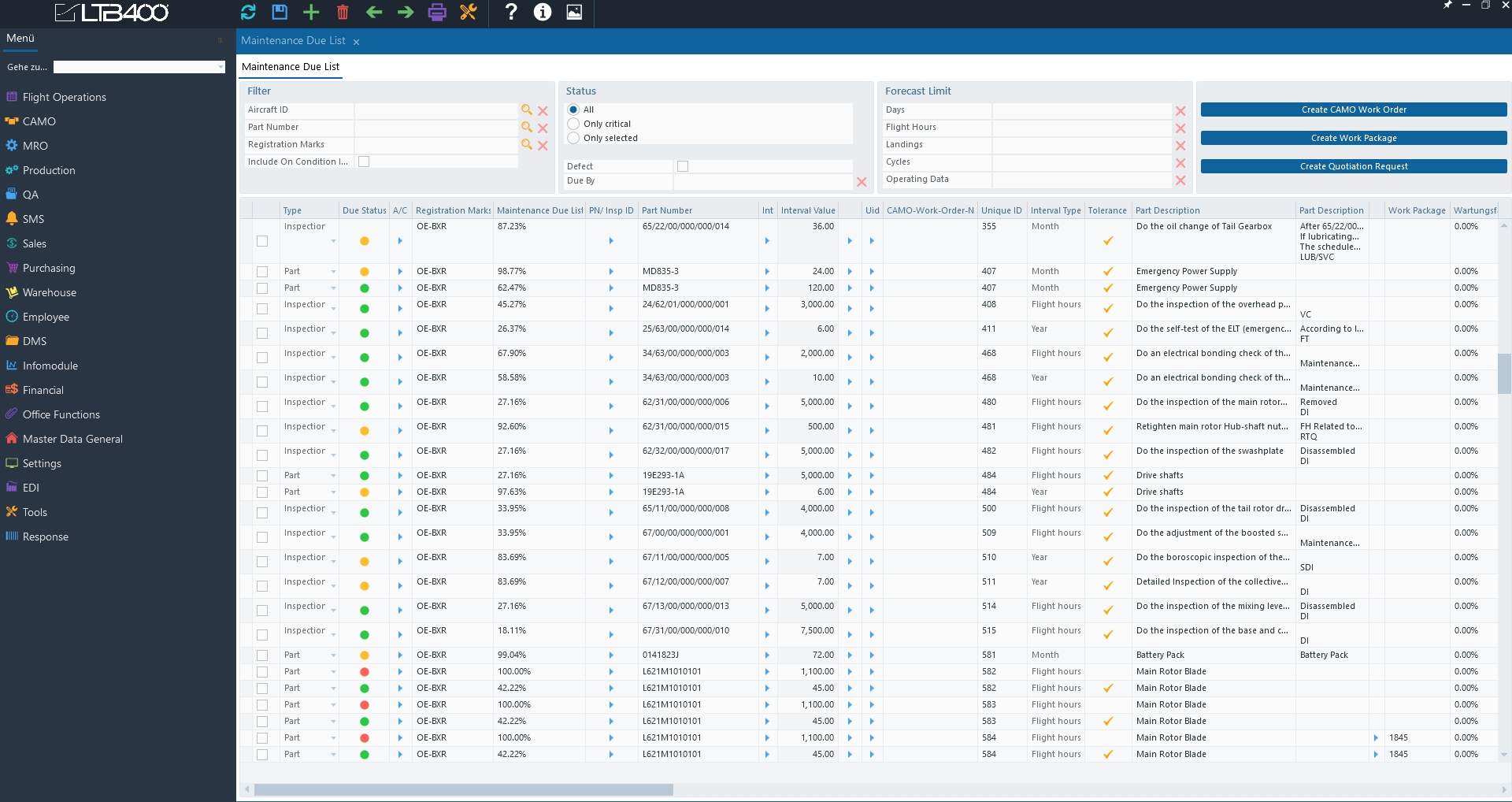

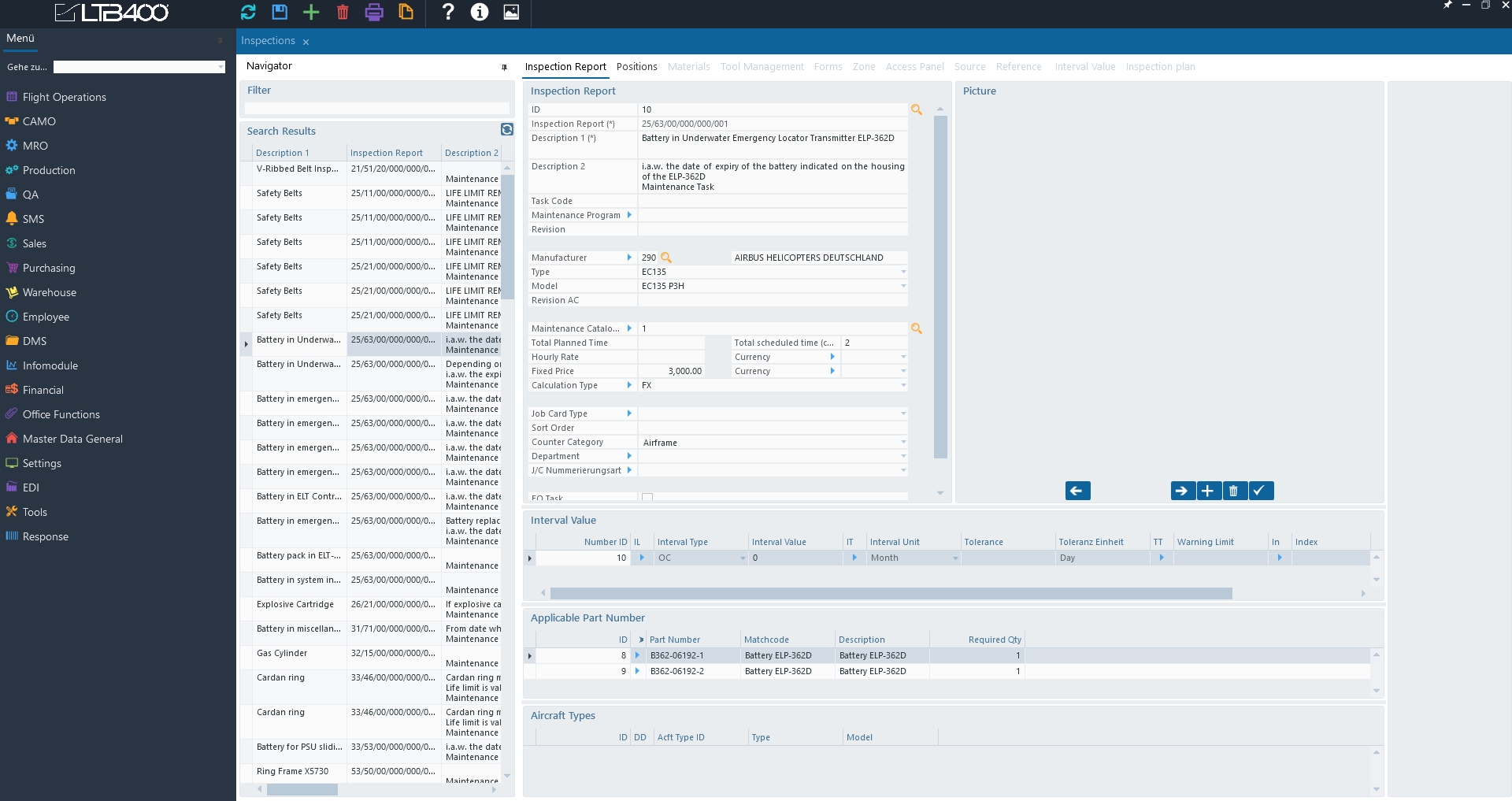

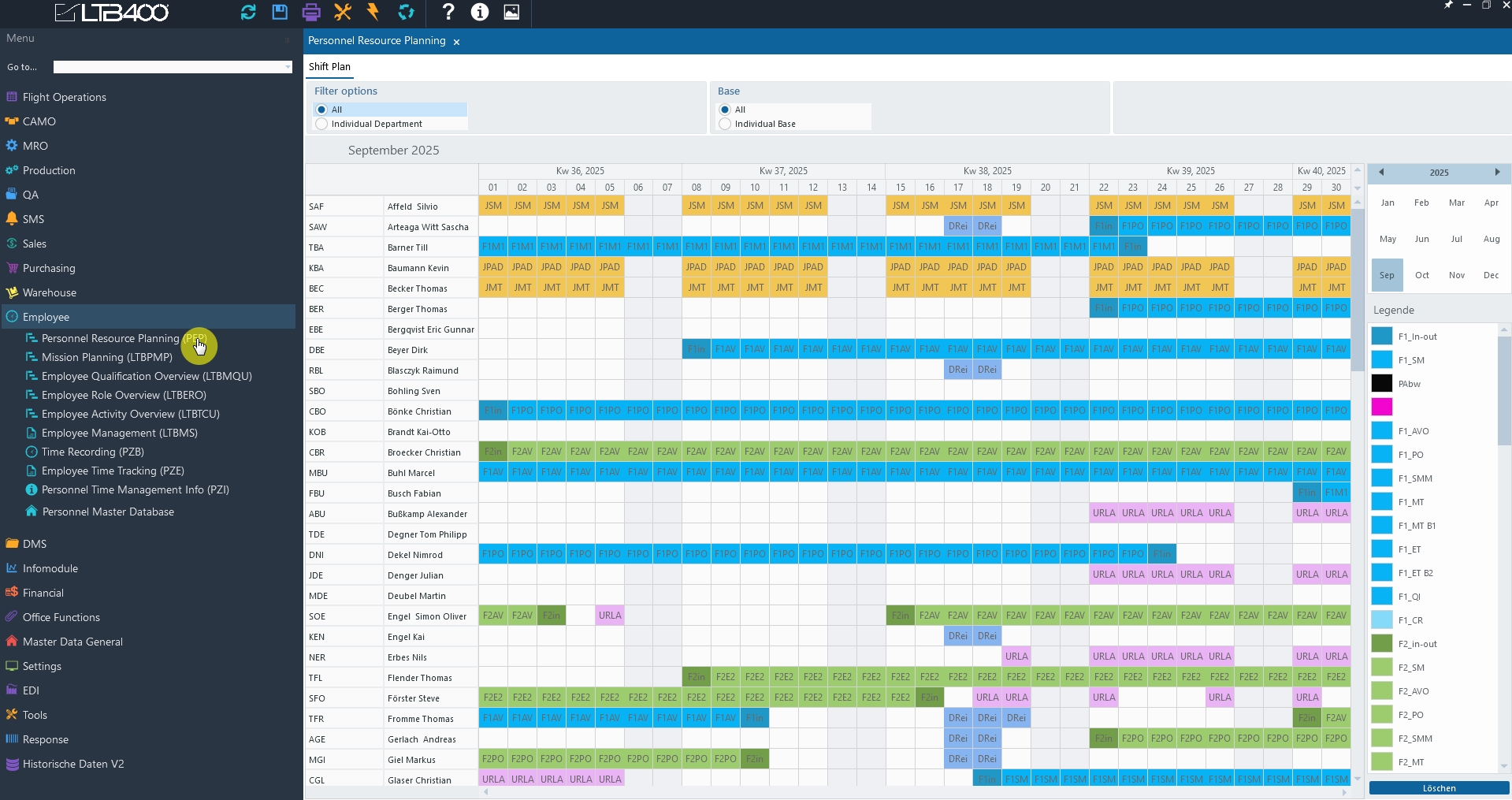

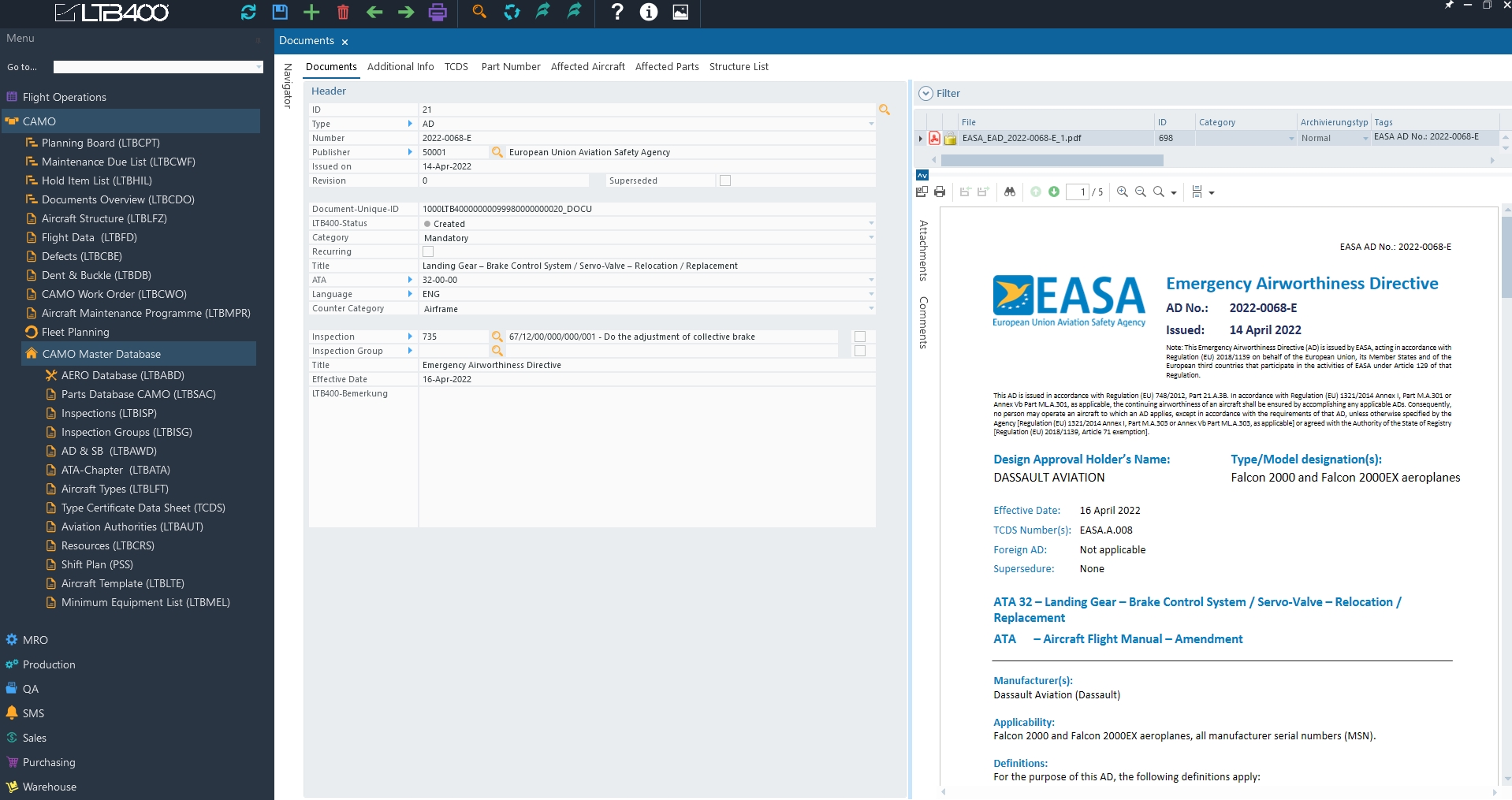

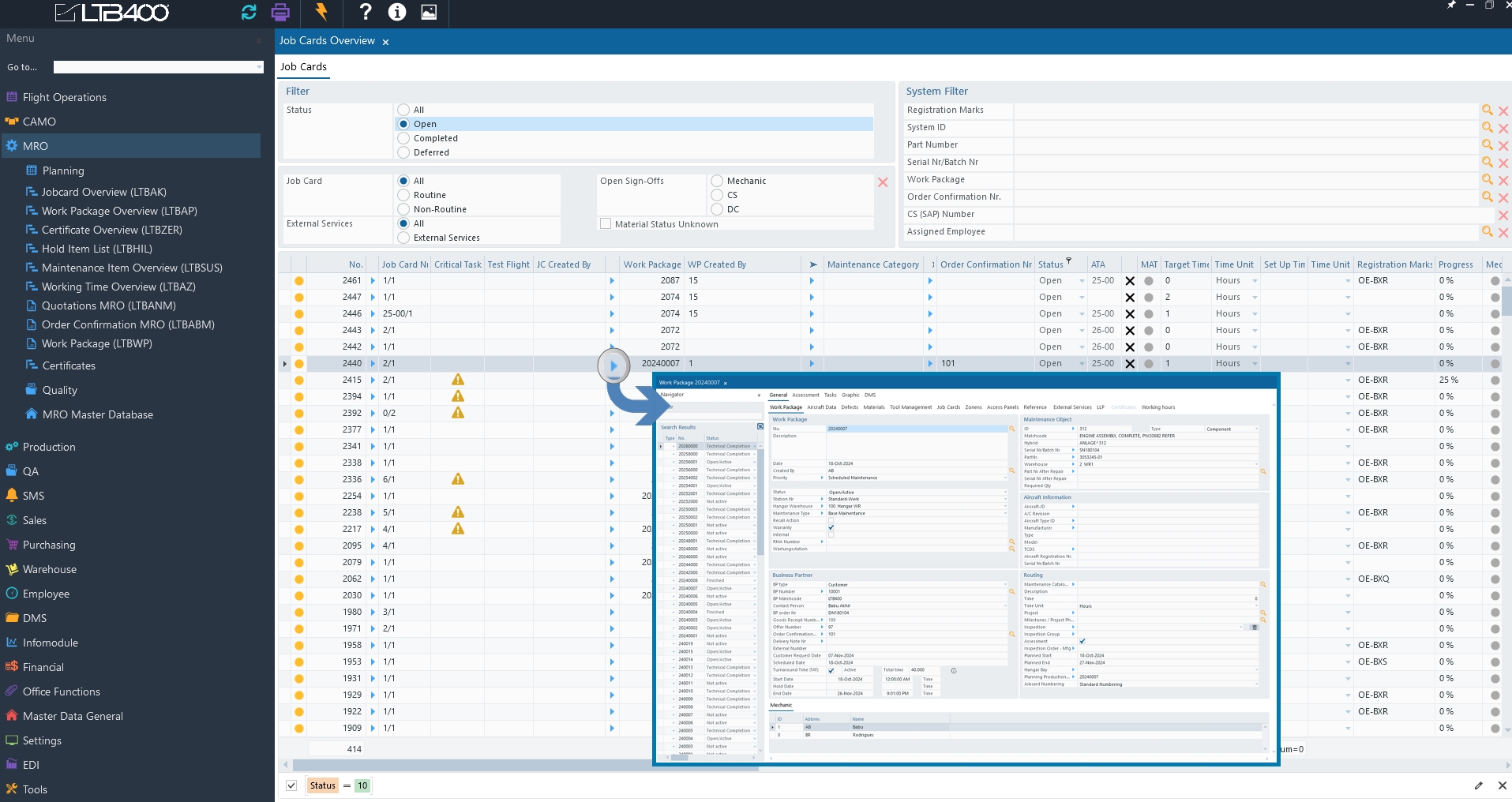

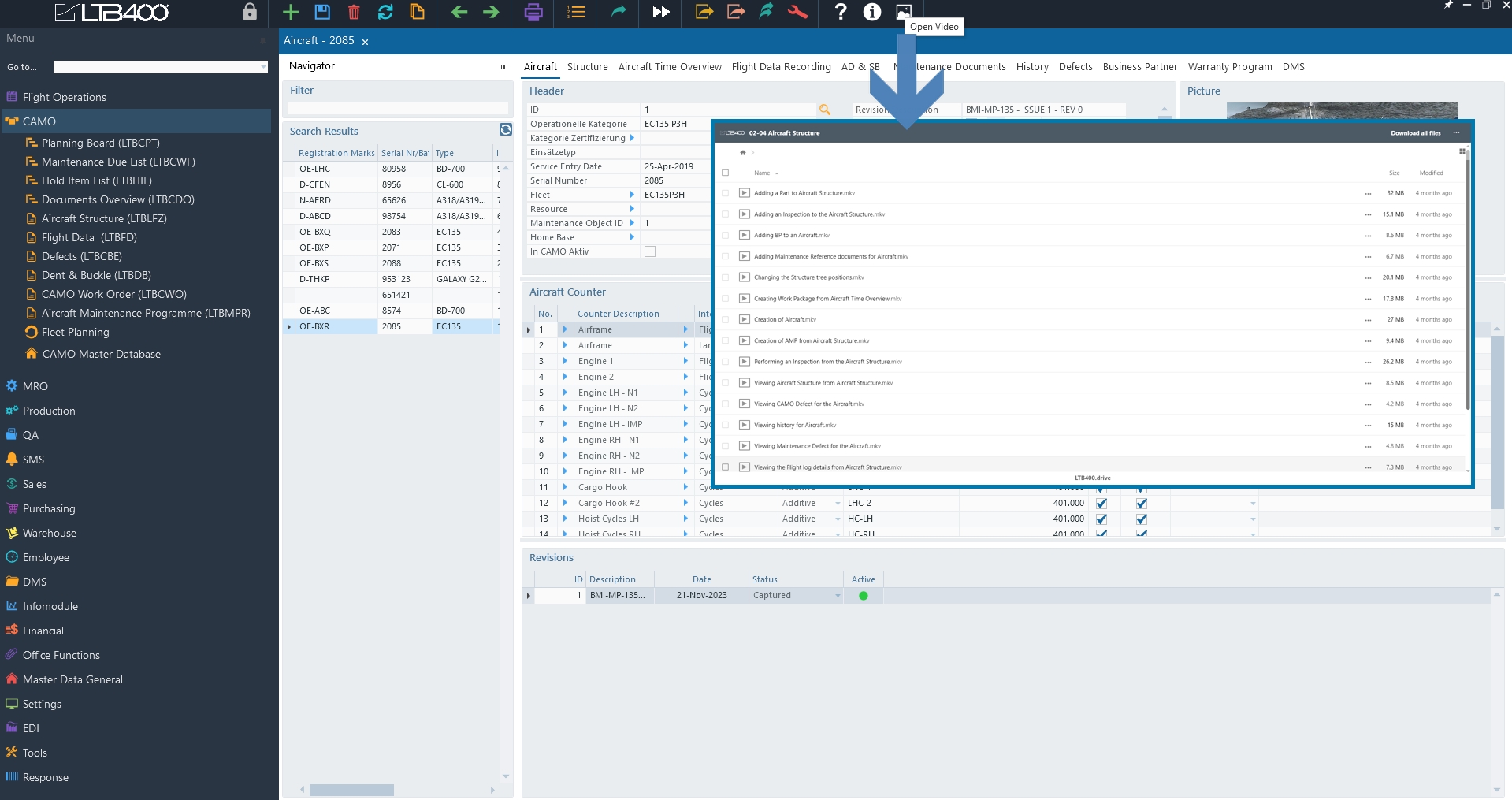

The titanium.aero offers a comprehensive maintenance scheduling system that enables operators to plan, track, and execute maintenance tasks with precision. It helps to keep track of upcoming inspections, part replacements, and routine checks, ensuring nothing is overlooked. Customizable maintenance intervals based on flight hours, calendar dates, or cycles allow operators to optimize their schedules. Real-time tracking ensures aircraft remain in airworthy condition, minimizing unexpected failures and reducing costly last-minute repairs.

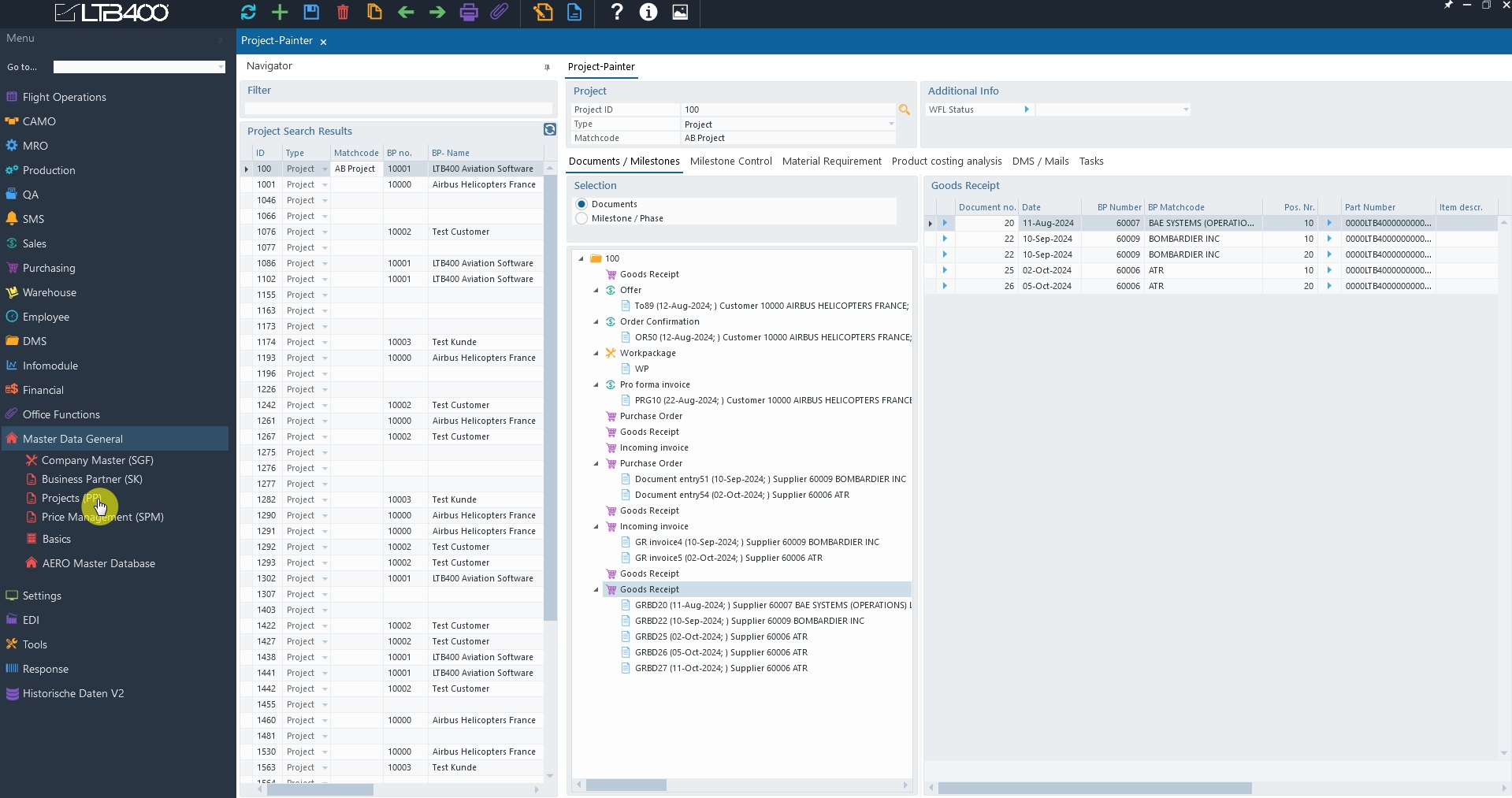

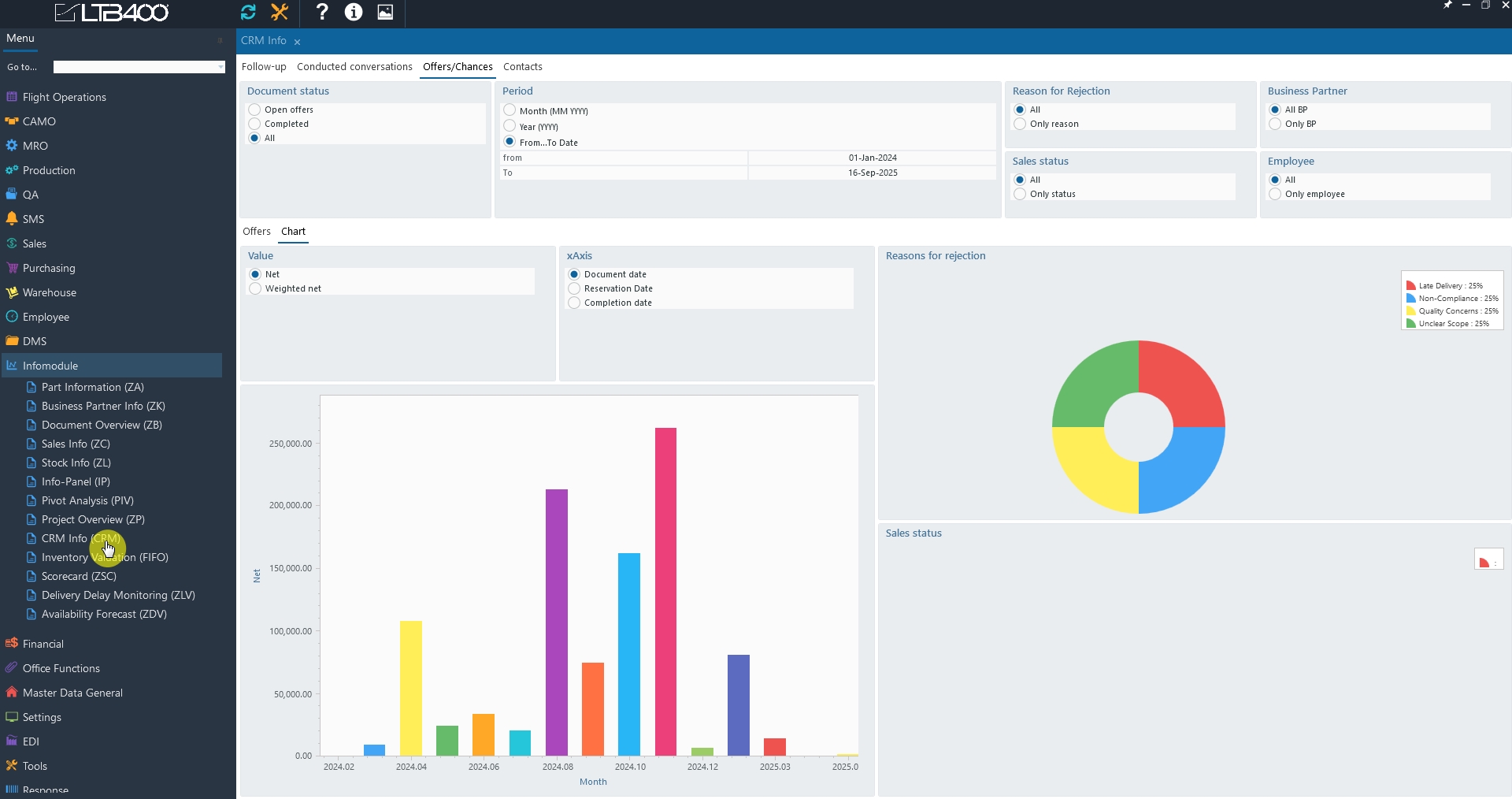

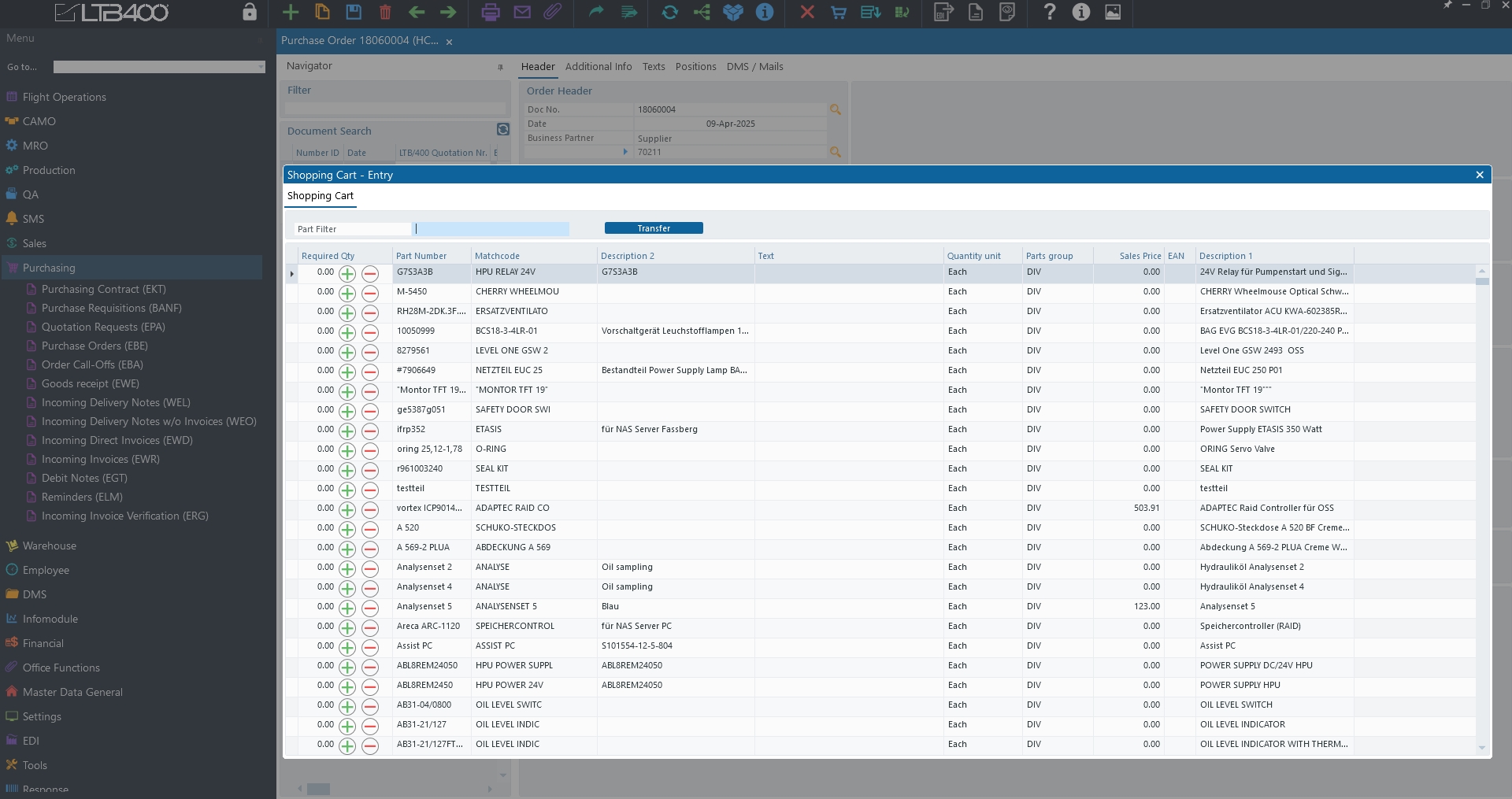

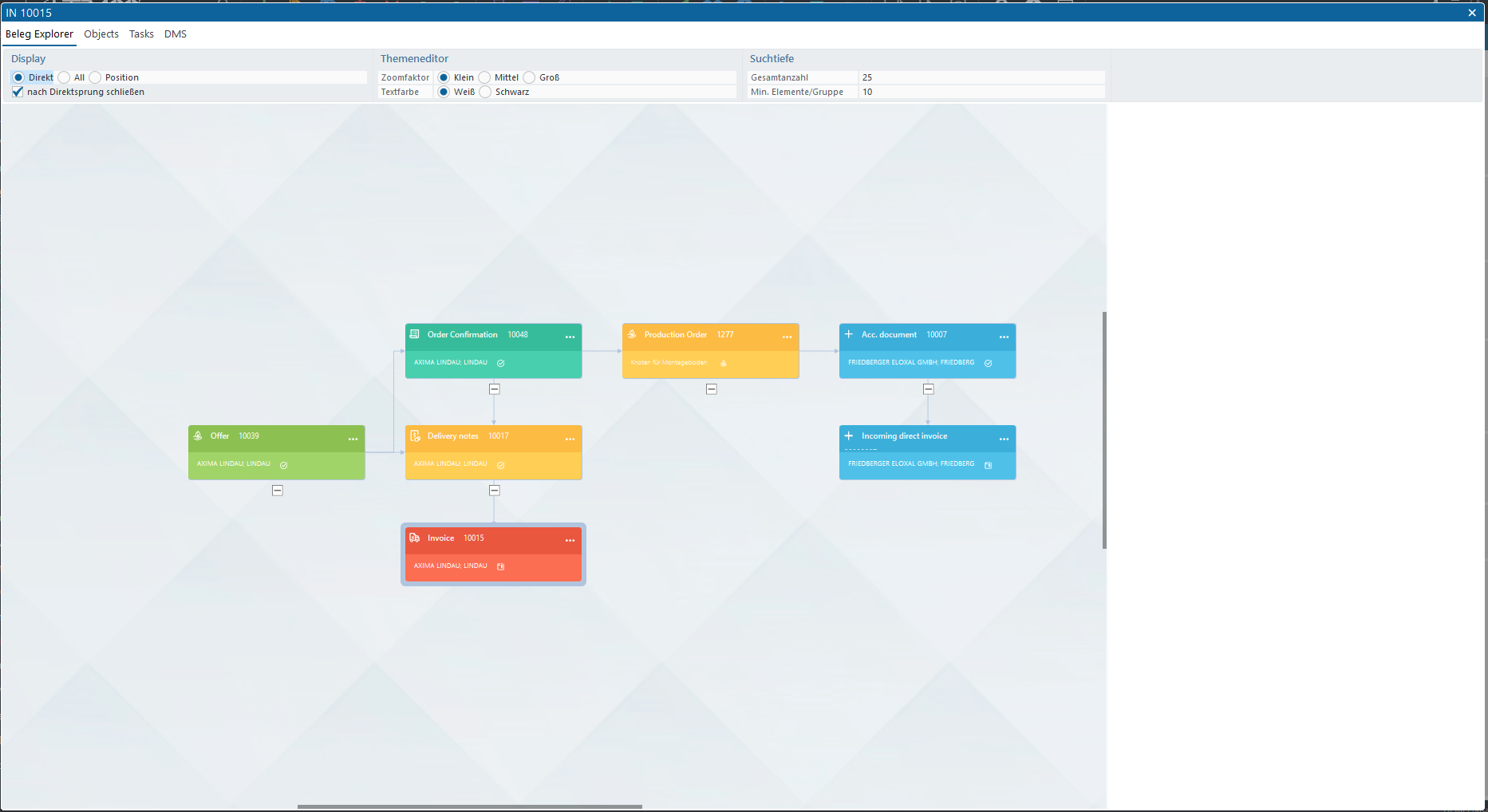

The titanium.aero seamlessly integrates compliance tracking with industry standards such as FAA, EASA, CAA etc. Automated updates on regulatory changes, digital logbook management, and audit-ready reports simplify the compliance process and eliminate the risk of fines or operational restrictions. A well-organized maintenance schedule not only ensures compliance but also optimizes resource allocation, reducing overtime costs and enhancing overall operational efficiency. Scheduling maintenance during non-peak hours, assigning tasks based on technician expertise, and improving spare parts procurement contribute to cost savings and increased productivity.